PRODUCTION PROCESS

The complete production process of iron table frames consists of 10 steps.

Step 1: Consultation and understanding customer needs to fully grasp their requirements and desires.

The production process of iron table frames starts with consulting and understanding customer needs. We engage with customers to understand specific requirements regarding size, shape, usage purposes, and other special requests. This helps us have an overall view of the desired product and design accordingly.

Step 2: Detailed technical design for the product, determining appropriate specifications, dimensions, and shapes.

After understanding customer requirements, we proceed with detailed technical design for the product. This process involves determining technical specifications such as type of iron, thickness, height, width, and other parameters. We also determine suitable dimensions and shapes according to customer requirements.

Step 3: Production planning based on design and customer requirements, determining production stages and assigning tasks.

Once the technical design is completed, we plan the production based on the design and customer requirements. This process includes identifying necessary production stages to create the final product. We assign tasks to each working group to ensure a smooth and efficient process.

Step 4: Cutting materials such as iron pipes and sheets according to the determined design using modern machinery for accuracy and quality.

After having a production plan, we proceed with cutting materials such as iron pipes and sheets according to the determined design. We use modern machinery like automatic pipe cutting machines, CNC laser cutting machines, and advanced technology to ensure accurate and high-quality cutting process. This helps us save time and effort in the production process.

Step 5: Performing drilling, pressing, and punching processes to create holes and suitable structures according to the design using specialized technology for accuracy and durability.

After cutting materials, we perform drilling, pressing, and punching processes to create holes and suitable structures according to the pre-determined design. These processes involve using specialized machinery like bending machines, pressing machines, hole punching machines to accurately perform drilling, pressing, punching operations while ensuring durability of the iron table frames.

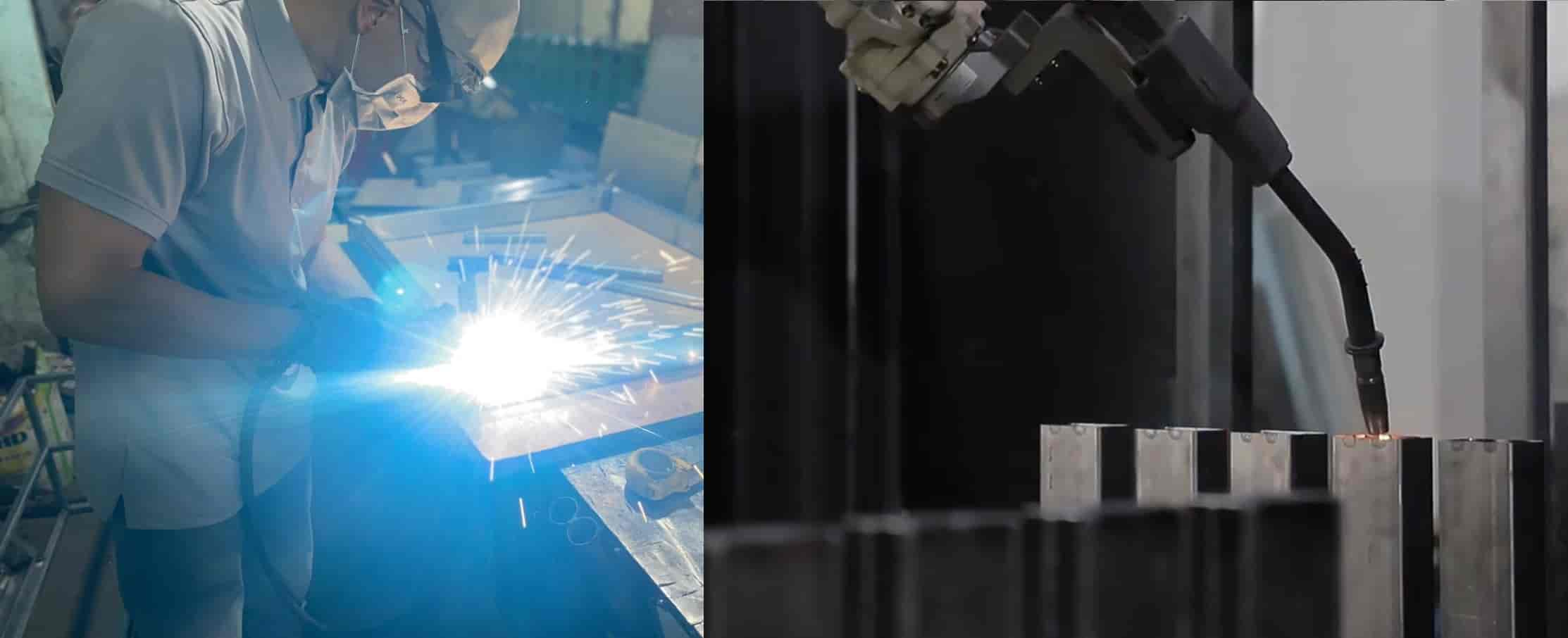

Step 6: Conducting welding process to assemble the components together, performed by skilled and experienced welders.

After completing the preparation stages, we proceed with the welding process to assemble the components together. This process is carried out by skilled and experienced welders who are proficient in iron welding. We also use welding robots for appropriate welding stages to increase productivity. We employ professional welding methods such as Mig and Laser welding to ensure accuracy and durability of the iron table frames.

Step 7: Grinding and cleaning the product to remove cracks, sharp edges, or dust on the surface, creating a smooth and beautiful finish.

After completing the welding process, we perform grinding and cleaning of the product. This process aims to remove cracks, sharp edges, or dust on the surface of the iron table frames. We use suitable tools and machinery to ensure that the surface of the product is smooth and beautiful.

Step 8: Surface treatment of the product to enhance adhesion and smoothness of paint layer, facilitating easy painting in future processes for optimal results.

After cleaning the product, we proceed with surface treatment to enhance adhesion and smoothness of paint layer. This helps in easy painting during future processes and ensures optimal results.

Step 9: Painting the product to enhance its beauty and color durability, using advanced and high-quality painting technology.

After surface treatment, we proceed with painting the product. This process aims to enhance the beauty and color durability of the iron table frames. We use advanced and high-quality painting technology to ensure that the painting process is carried out accurately and delivers the best results.

Step 10: Quality inspection of the product before packaging and storage, ensuring that the finished product meets technical requirements and quality standards before reaching the hands of customers.

Before packaging and storage, we conduct a thorough quality inspection of the product. This step ensures that the finished iron table frames meet all technical requirements and quality standards. We check for any defects or issues to ensure that only high-quality products are delivered to our customers.